The choice of whether or not to include a weld camera in the design of an automated welding system is one of the quickest and easiest decisions for some of our customers. But do you have any idea why?

In this post, we’ll explore 4 of the key benefits of using weld cameras and why you should consider integrating them onto your automated welding system.

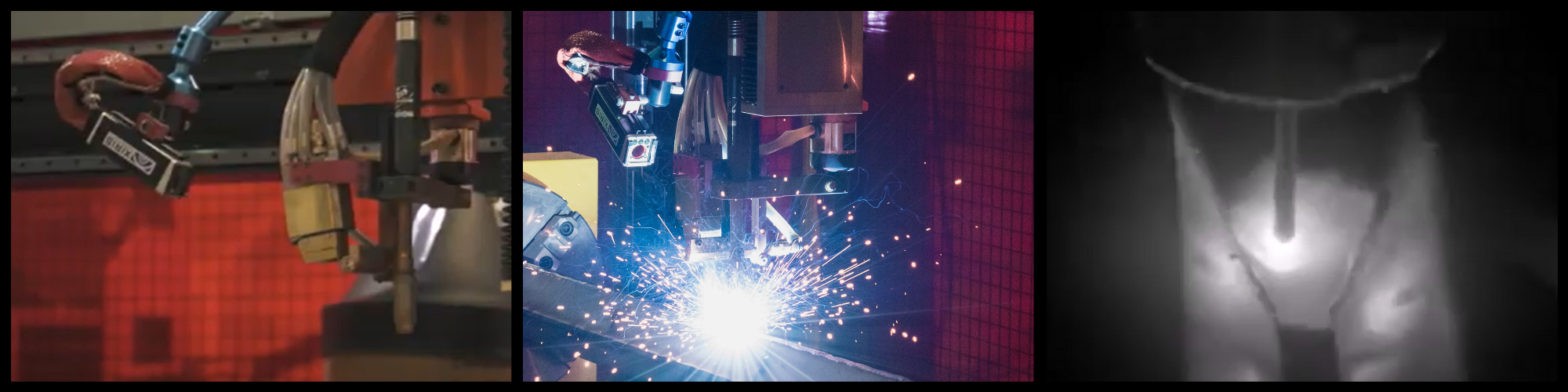

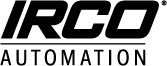

All of the welding systems featured in this post and video (below) have Xiris cameras integrated onto them. There are various camera models and setups you can choose from, but most of the time it depends on your weld process. For example, in the picture above, the weld camera shown mounted on the weld head has remote focus and built-in LED to assist with setup and automatically switches to weld mode once the arc starts. Pretty handy, right?

4 Reasons to Include Weld Camera on your Automated Welding System

Sections:

- Weld Cameras to help increase / improve on Health and Safety

- Weld Cameras for improved Weld Monitoring

- Weld Cameras to improve Run-time and operational Productivity

- Weld Cameras for weld video recording

- Video: 4 Reasons to Include Weld Camera on your Automated Welding System

1. Weld Cameras to help increase / improve on Health and Safety.

As with any weld process, but in our case ones being carried out by an automated welding system, it’s important for operators to be able to see all the elements of the environment around a weld. In some cases, an automatic welding environment can be too dangerous or congested for an operator to go in close enough to directly monitor the weld process.

Weld cameras address these immediate safety concerns by allowing the operator to remotely view and monitor the weld process as it’s happening.

2. Weld Cameras for improved Weld Monitoring

Weld cameras provide operators a clear and defined view of the weld wire and its surrounding area allowing a variety of parameters to be monitored. These parameters could include ensuring that the weld wire is in the weld joint, monitoring the size of the arc, or the condition of the weld pool.

Being able to identify specific parameters using the camera prior to welding, allows for reduced setup time, and from one place rather than having to go back and forth.

Also, being able to identify anything that’s a little off, before the weld gets too far, allows the operator to interrupt the weld process to reduce potential rework.

3. Weld Cameras to improve Run-time and operational Productivity

In the example of our linear robot design, our automatic laser seam tracking system makes adjustments based on the changes in the weld path it senses. However, in weld processes that do not have seam tracking, weld cameras provide real-time monitoring so the operator can make adjustments as needed to help minimize bad welds and rework.

In many cases, the use of a weld camera can help increase your on-arch-time because it reduces the operator's need to stop the weld process to see the weld result or adjust. Being able to monitor the weld process remotely as it’s happening, the operator doesn’t need to stop the system to check and then restart again.

4. Weld Cameras for weld video recording

For some of our customers, one of the most important benefits of weld cameras is their ability to record and capture live video of the welding operation. This means the weld process can be recorded, stored, and reviewed off-line and even on a different device. Recording can be an essential step for process verification and improvement. Often, our customers like having the ability to playback their weld video in slow motion for process analysis.

Weld cameras allow for far more detail to be monitored in the welding process than ever before.

Conclusion

If you’re looking to improve your welding process, weld cameras are worth consideration. In many of our solutions, integrating a camera is one of the quickest and easiest decisions to make as the benefits range from improved safety, real-time adjustments, or off-line weld reviews.

Can you think of any other benefits?

Let us know on our LinkedIn Post here!

Video: 4 Reasons to Include Weld Cameras on your Automated Welding System

[The weld cameras featured in this video are all from Xiris Automation]

Interested in learning more about Welding Automation or the different systems that were featured in this video?

To get in touch with one of our welding automation specialists, send us an email: info@ircoautomation.com or schedule a meeting here.

Or, explore and learn more by visiting one of these pages:

- Quick Guide: Automated Beam Welding Systems

-

Automated Reaming Stations: A Simple Addition to Maximize Productivity

- NEWS: Linear Robot for Box Beam Welding

For more information on Xiris' Weld Cameras,

click through to their website via the image below.

To return to our main home page, click here.

.png)

.png?width=600&name=Author%20Headers%20(7).png)